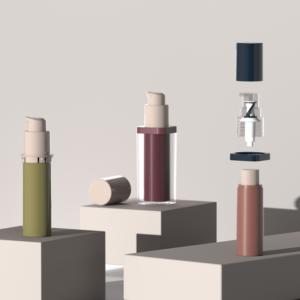

Airless Bottles for Skincare Brands

Built for Consistent Production and Formula Protection

Airless Packaging Trusted by Established Skincare Brands

For 30+ years, we’ve helped skincare brands protect active formulas, reduce waste, and scale production with confidence.

Find the Best Airless Format for Your Formula

Compare bottles and jars based on viscosity, dispensing needs, and sustainability goals.

A Clear Path From Quote to Delivery

You approve decisions. We manage samples, files, documentation, production, QC, and freight.

Get a Quote for Custom Airless Bottles or Jars

Submit your info to get pricing, samples, and expert support.

Frequently Asked Questions

Are airless bottles recyclable?

Many are made with recyclable materials such as PP. Mono-material designs are available for 100 % recycling. Find them here.

How do I test if my formula is compatible with airless packaging?

Place ~3mL of formula in your palm horizontally → turn hand vertical.

If the product runs down, it is likely compatible.

If it stays in place, the viscosity is too thick.

What are the benefits of choosing airless instead of a standard pump?

Airless packaging protects air-sensitive active ingredients, preserves product freshness, reduces contamination, improves shelf life, and ensures controlled, premium dispensing.

Why doesn’t my airless bottle pump at all?

Air pockets during filling can prevent the piston from meeting the product. Work with experienced fillers to ensure air removal and consistent fill height.

Why does it take multiple pumps before product starts dispensing?

The pump must be primed until the piston rises enough to contact the product. This is normal on first use but can be minimized by proper filling + pump selection. 1-3 pumps is ideal.

What dosing/output options are available?

Common outputs include:

0.15mL • 0.20mL • 0.30mL • 0.50mL • 1mL

Custom outputs available depending on bottle series + viscosity.

Can airless bottles handle toothpaste-thick formulas?

Yes — some pumps are specially engineered for high-viscosity formulas like pastes or balms. Ask us for the best pairing by viscosity.

Do you offer refillable airless bottle options?

Yes — multiple refillable models are available with removable pump components. (We can recommend the right series based on your sustainability goals.