Customization Showcase

ABOUT

With over three decades of experience, we create custom packaging to help your brand tell its story. Color, finishes, printing techniques, and unique elements communicate your brand’s essence, leaving a lasting impression. Even small details can make your product stand out, grabbing attention and influencing sales. From striking designs, tactile experience, or awe- inspiring effects, TPC can help you transform your idea from concept to conception.

LLLLLLOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOONNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

COLOR

IN-MOLD

Injection molding is a manufacturing process that creates parts by injecting heated and mixed materials, like glass and plastics, into a mold. As it cools down and hardens to the shape of the cavity, it’s the ideal moment to integrate your desired color directly into the material, rather than adding it afterwards.

ANY PANTONE COLOR!

We can print any Pantone color. For accuracy, please refer to Pantone color books (Pantone coated/uncoated; metallic coated/uncoated). If your color is outside these books, provide Pantone chips.

LLLLLLOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOONNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

PRINTING

SILKSCREEN

A process by which ink is pressed through a photographically treated screen onto a surface. One color is applied at a time with a new screen for each color.

Benefits of Silkscreen Printing:

- Slightly raised ink can give texture

- Great for 2-3 colors

- Light-resistant

HOT/FOIL STAMP

Colored foil to applied to a surface through a combination of heat and pressure. Colored foils are often gold and silver, but other colors are also available to create a truly signature design.

Benefits of Hot Stamping:

- Shiny appearance is eye-catching

- Design is premium and luxurious

DIGITAL PRINTING (CMYK)

CMYK – which stands for Cyan, Magenta, Yellow, and Key (Black) is a four-color processing and allows the creation of a broad spectrum of colors by blending these primary inks in varying degrees.

Benefits of CMYK Printing:

- Vibrant and Accurate

- Cost Effective

- Uniform in color across large print runs

- Suits a wide range of materials

HEAT TRANSFER

This technique involves digitally printed labels that are pressed on with heat.

LLLLLLOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOONNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

FINISHING TOUCHES

UV COATING

Finishes include frosty, matte, satin, semi-gloss, and glossy (in order from least to most shiny). A final coat is applied on printed materials cured by ultra-violet light.

Benefits of UV Coating:

- Can make plastic mimic the look of metal

- Protects surfaces from scratching

- Resistant to chemical abrasion

- Stimulates the touch sensory, leaving a lasting impression

REVERSE OXIDATION FINISH

In this process, ink is first buffed to achieve the desired color. The initial artwork is applied and then subjected to oxidation. This is followed by a second printing of the artwork, another round of oxidation, and finally, the surface is buffed again to reveal the remaining artwork.

Benefits of Reverse Oxidation Finish:

- Creates a high contrast and elegant artwork

- Adds a sleek shine to the product

EMBOSS & DEBOSS

Embossing creates a raised image and debossing creates a recessed image. These techniques add branding value to the package by creating a unique logo design that consumers can touch and feel. This effect is created with a custom tool. 2 height levels available.

LLLLLLOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOONNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

CUSTOM INSERT TRAY

When your customers open the tin and see the product perfectly nestled within the custom tray, it should evoke feelings of awe and excitement. We provide fully customizable tray inserts for all our tins.

CUSTOM INSERT TRAY DESIGN PROCESS

Send Samples

Please send samples of your pre-rolls or edibles to our office at 2310 East 4th St, Long Beach, CA 90814.

Fitting Assessment

Our engineer will assess if the desired quantity fits the chosen tin size. If feasible, we will create a drawing of the custom tray.

3D Prototype

We can print a 3D prototype of your custom tray design in plain white resin material. Contact us for pricing and lead times.

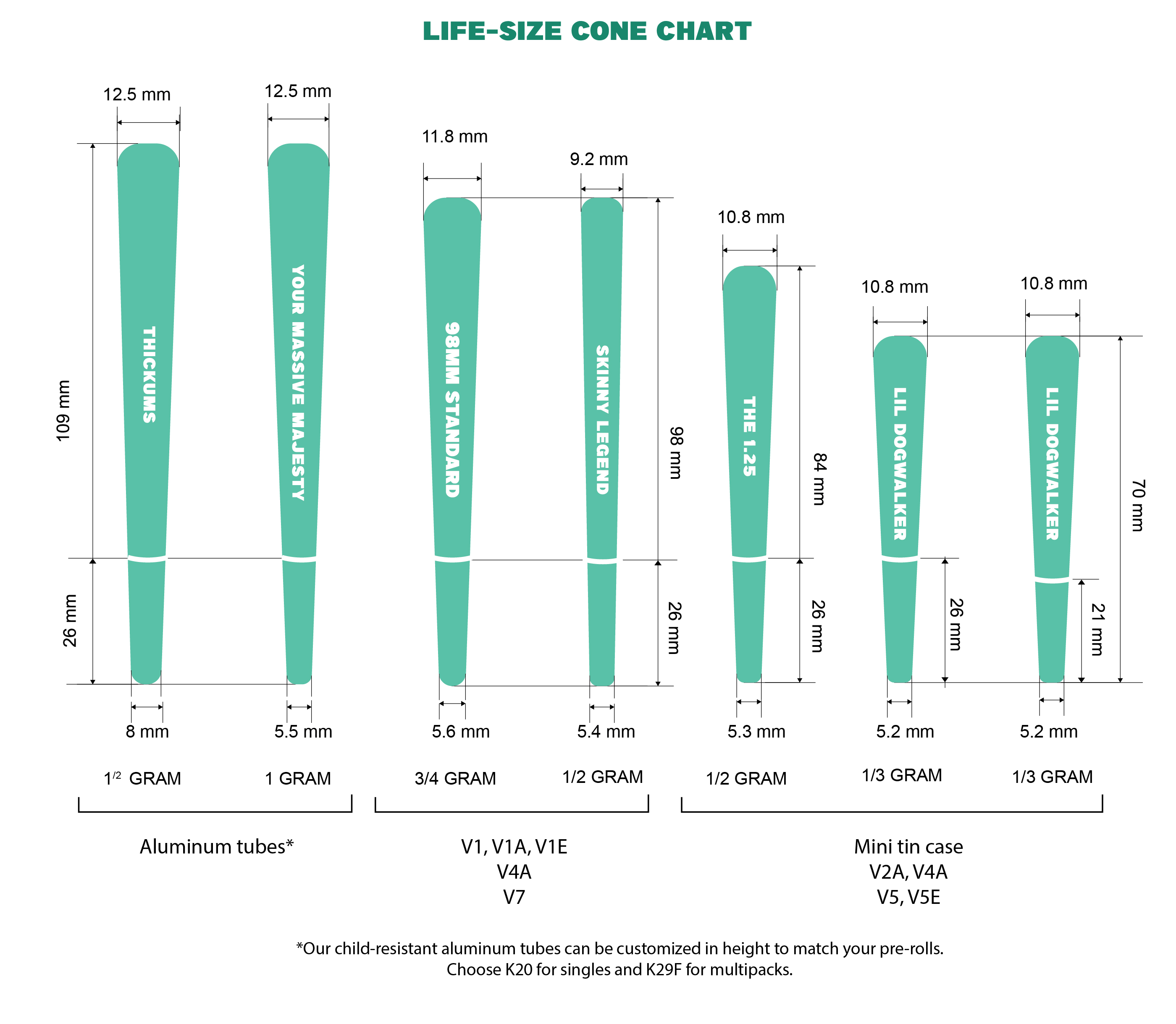

STANDARD PRE-ROLL SIZES

If your pre rolls are of “standard” industry size, review our pre roll size chart and the corresponding tins. We may have an existing tray for you!

MATERIAL OPTIONS

We offer a range of materials for the trays, including standard PP (available in any PMS color), Paperboard, EVA Foam, PLE (Bioplastic), and Tin.

With 30+ years of experience, we’re the premier packaging manufacturer. Let’s create magic!