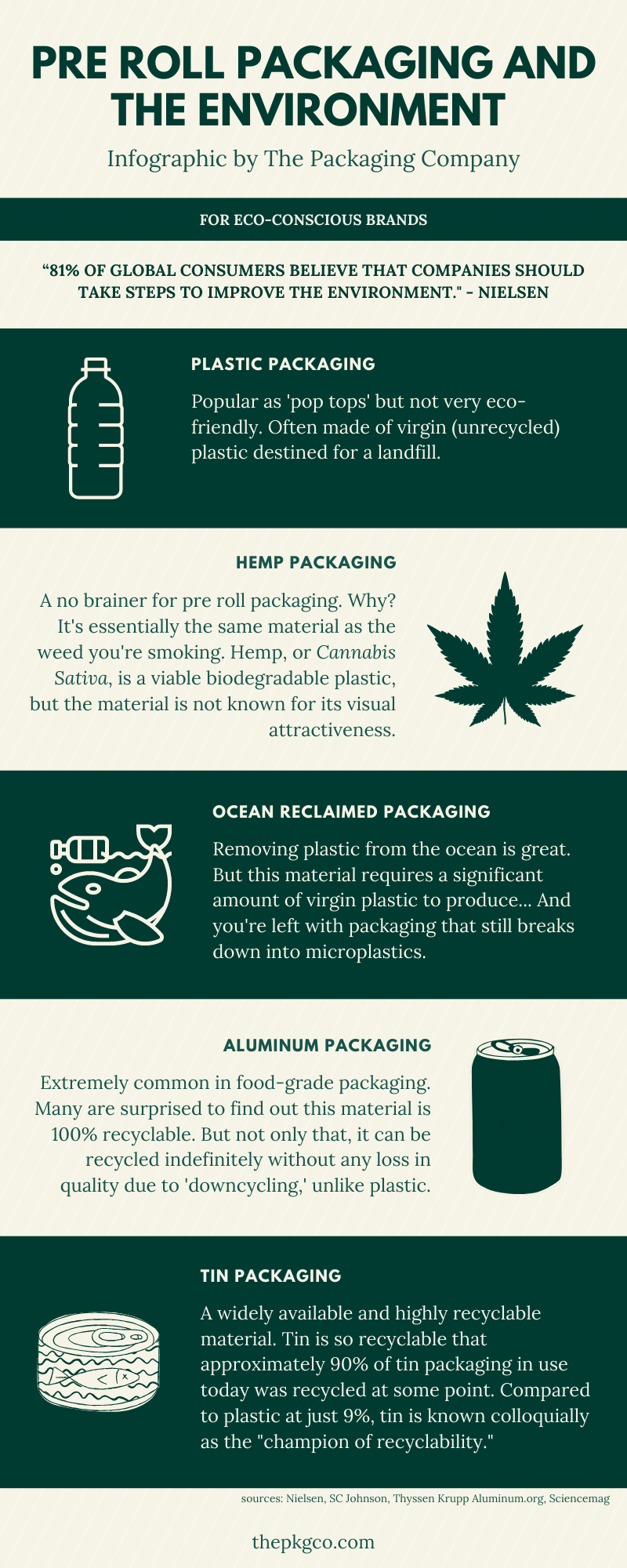

Ocean-reclaimed plastic’s popularity is relatively recent and comes off the heels of documentaries such as “Seaspiracy” on Netflix highlighting the amount of plastic waste currently floating in the ocean. Much of this plastic is essentially non-biodegradable and will slowly break down into the infamous “microplastics” currently wreaking havoc on global marine ecosystems.

The answer for many brands is to switch up their plastic packaging for ocean-reclaimed plastic.

The biggest issue with ocean-reclaimed plastic is blatantly obvious- the plastic itself, though reclaimed from the ocean, is no more biodegradable than before when it was first discarded. It’s also commonly manufactured using anywhere from 25% to 75% virgin plastic.

Due to this fundamental issue, ocean-reclaimed packaging is likely destined for the same landfill or to end up floating in the same ocean we know and love—as it’s no more biodegradable than before and perpetuates the use of virgin plastic.

Cleaning up and reusing these non-biodegradable plastics is undoubtedly a necessity, as no one wants plastic waste floating in the ocean. But ocean-reclaimed plastic, though cleaning up the ocean in one sense, is similar to “kicking the can down the road” as its plastic will still end up in a landfill at some point in the future.

While most companies require a significant percentage of virgin plastic to bind their ocean-reclaimed plastic together, SC Johnson recently created a proprietary technique for 100% ocean-reclaimed plastic packaging, which is a big step in the right direction. But, once again, it does not solve the overarching problem of the material itself being non-biodegradable.

Aluminum

“The environmental appeal of aluminum is due primarily to its recyclability. In addition to being 100% recyclable, aluminum can also be recycled indefinitely without a significant reduction in quality.”

Aluminum packaging is another upstart in the pre-roll scene, but definitely not new to packaging. Common aluminum cans are an extremely popular use of this material, and many would be surprised to learn that aluminum is one of the most eco-friendly and recyclable materials out there today.

Compared to plastics, aluminum does not ‘downcycle,’ meaning the material quality and recyclability does not degrade with each recycling process. In plastic, this would typically require more virgin plastic to make up for any difference in quality lost due to downcycling.

The disparity is staggering when considering the recyclability of aluminum. “Almost 75% of all aluminum ever produced is still in use today,” according to the Aluminum Association. “By contrast, only 9% of plastics ever produced have been through the recycling process.”

Part of the reason behind this great disparity is energy consumption in the recycling process. “Unlike plastic packaging, aluminum products do not need to undergo complicated sorting before recycling. Additionally, the energy consumed during the aluminum recycling process is significantly less than that for plastics, leading to lower recycling costs and reduced carbon emissions” (Aluminum Association, Thyssen Krup).

All in all, aluminum packaging is a widely available, food-safe, and environmentally friendly way to package your pre-rolls and keep them fresh.

Tin

“The greatest strength of tinplate is its incredible recyclability.”

Another highly recyclable metal is tin. How recyclable is it? “In Germany, the material has consistently exceeded all required recycling rates for 10 years. In 2018, a whopping 90.4 percent of the tinplate used as packaging material in Germany was recycled – in Europe the figure was 82.5 percent. This makes tinplate the recycling champion among packaging materials.”

90.4% is quite high for packaging materials, making tin quite similar to aluminum in terms of recyclability.

Another bonus of tin packaging is that it is often more reusable than plastic as well, with vintage tins lasting decades and ending up as collector items due to their longevity. Who knows, hold onto your tin packaging long enough and it could be worth a lot more in the future!

Conclusion

If brands value the environment, there are many alternatives to virgin plastic out there to package your pre-rolls in. It’s up to brands to decide on what is best and most suitable for their product while balancing the needs of the environment and sustainability. Thanks for joining us on this deep dive into pre-roll packaging.

Join us next month for more pre-roll news!

We made the infographic below to highlight the main points: